I am LOVING my new kitchen nook area! I had a larger table, that I built for this spot when we first moved in, that had six chairs and the chandelier was in the middle of the ceiling. This cramped up the space so much (sometimes you don’t know exactly how you will use a space in your home until you have lived in it for a while). The majority of the traffic through our house is the door in the kitchen that leads from the garage. So, I had an electrician out doing some work and asked him to move my chandelier to center it on the bay window nook. Then, I decided to build a smaller table with a built-in bench 🙂

I couldn’t be happier now! I love this table, I love how it is centered in front of the bay window and the chairs are the icing on the cake!! You can find the chairs HERE! (*** The chairs come in a set of 2 and are priced for a set***)

The best part? I built this table for only $75 in lumber! You can click HERE for the free printable plans and follow along with the how-to tutorial below 🙂

My first step was to rip the round edges off of each 2x board. This is a bit time consuming but it makes the table look nicer and it creates a smooth table top. You don’t have to do this but you will have “crumb catchers” on your table top if you don’t 😉 I used my Ridgid table saw (which I LOVE) but you can purchase a less expensive table saw and get the job done just fine. It’s a great investment if you plan to build lots of furniture 😉

Just set the guide on your table saw about 1/8″ less that the width of the board you are ripping. A 2×4 is 3 1/2″ wide so I set it for 1/8″ less than that.

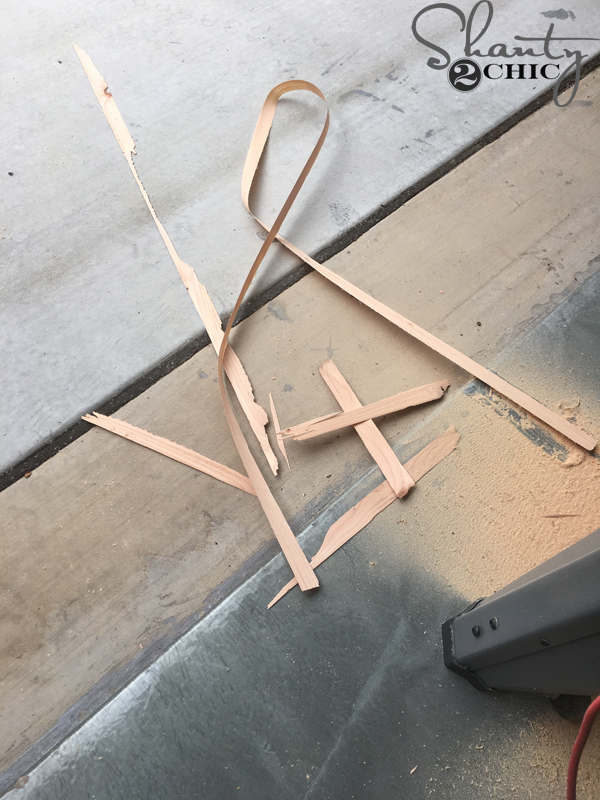

Once you make one cut on one side of every board, flip them over, take another 1/8″ off of the width and cut the other sides. Total you will cut about 1/4″ of the width off of the boards total. The pic above is the “waste” from the rips.

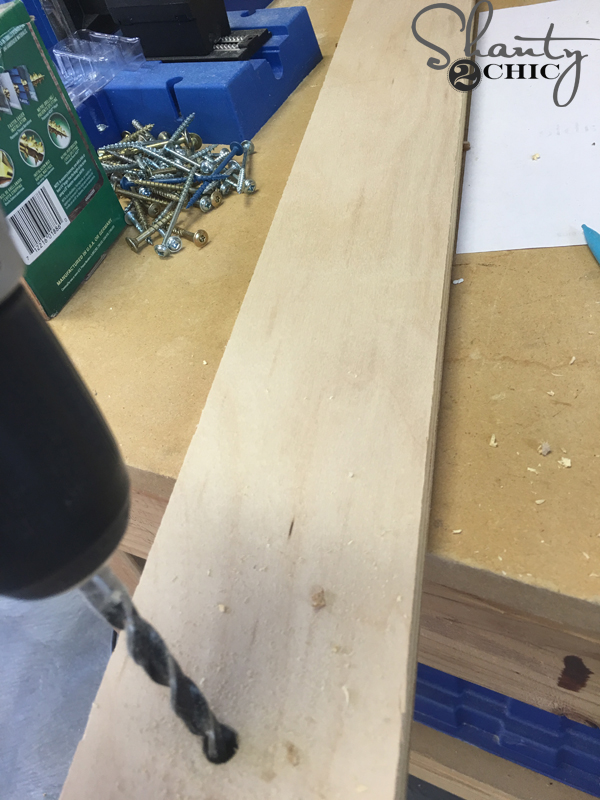

Next, I used my Kreg Jig to drill 1 1/2″ pocket holes into the 2×4 planks. You can find the Kreg Jig K5 model that we love HERE on Amazon.

Then, I attached all of the planks together with 2 1/2″ pocket hole screws.

This creates the table top that you will cut to make round. Notice where I put the pocket holes. You want to make sure that they will clear the cuts you make for the round top.

Next, mark the very center of the planked top.

Then, cut a scrap board that is longer than the radius of your table and drill one pilot hole at one end.

Then, measure from the center of that pilot hole and make a mark that is the length of the radius of your table.

Hammer a nail into the mark that goes into the bottom of the table top at the very center mark that you made on the table top. Then put a pencil in the pilot hole and drag the scrap board around the table top planks. This will mark an even circle for you to cut!

Once the circle is draw, you can use a router or a jigsaw to cut the circle. A jig saw is much less expensive and will work just fine. I used mine, just make sure to cut slow and don’t lean into the jigsaw. This will cause the blade to bend on the 2″ thick boards and give you a “wonky” cut. No worries, just go slow 🙂

Now, make your cuts for the table base and apply glue to the 2×3 pieces.

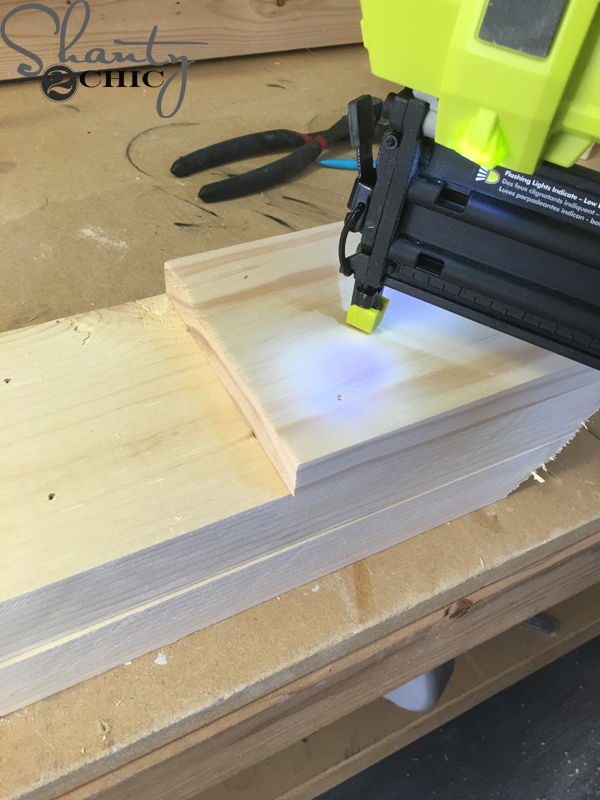

I used my Airstrike 18 gauge nailer with 2″ brad nails to attach the 2×6 board to the 2×3 boards.

It should look like this. Now, you can attach the other 2×6 board the same way.

Make sure to sand the base so that the base looks like one solid piece of wood.

Here she is 🙂 Now, let’s build her some feet 🙂

Now, Make all of the cuts for the legs and supports and drill 1 1/2″ pocket holes in one end of half of the boards. Make sure to keep the pocket holes towards the center of the 2×6 boards. These will be covered with 1×3 blocks.

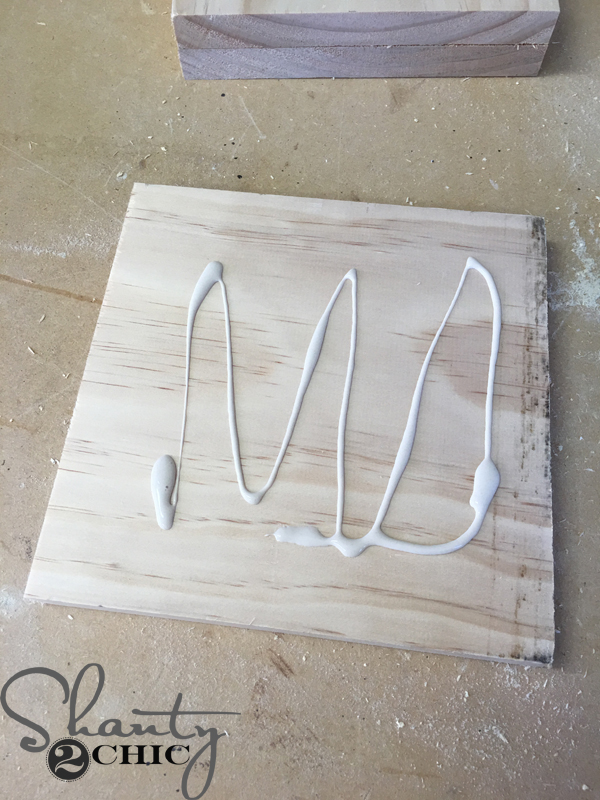

Apply glue to a 2×6 board with pocket holes (glue goes on the side that does not have pocket holes)

place it on top of a board that does not have pocket holes and attach them with 2″ brad nails.

Once the glue dries, you should have 8 blocks of 2×6 that you have attached together. Now, you can use your miter saw to cut the angles off of the ends of the blocks (refer to the plans for the exact angle measurements). To make these angle cuts, you will adjust the top of your miter saw so that the top swings to the angle you want to cut. This is called a bevel cut. This is the first angle cut. (***Pocket holes should be facing up on these cuts).

The second angle cut is off of the top piece. If you don’t feel comfortable making this cut, you will get the same overall look if you skip this step. No worries.

Cut the pieces for the foot pads and attach them to the four feet with wood glue and brad nails.

Now, you should have 4 table top support pieces and 4 feet with foot pads on the bottom.

Attach a foot to each side of the table base with wood glue and 2 1/2″ pocket hole screws.

When you have attached all 4 feet your table base should look like this.

Cut the 1×3 blocks and attach them to the table base with 1 1/4″ brad nails and wood glue. Start with the vertical pieces first.

Then follow up with the horizontal pieces. Attach them the same way. This will cover up the pocket holes 🙂

Here is the table base with the blocks attached.

Now, flip the base upside down and attach the top supports and blocks the same way.

Make your 1×8 cuts and attach two pieces together with wood glue.

And let them dry. If you don’t want to wait for the glue to dry, go ahead and do this step at the very beginning of your build. This way, the wood glue should be dry in time for you to cut the corbels 🙂

I used my jigsaw and cut 8 corbels from the 1×8 blocks. Then, I applied glue to the back sides and attached them to the table base with 1 1/4″ brad nails.

Do this for all 4 feet and supports and it’s ready for the finish!

I painted the table base Antique White by Sherwin Williams.

While I waited for the paint to dry, I stained the table top. I used Varathane Early American stain (find it HERE on Amazon) and applied it with a lambswool applicator. This is by far our favorite way to apply stain. The lambswool is a bit pricey but it is worth the cost when you are staining a large piece. It makes it so much faster to stain – trust! You can find the Lambswool HERE on Amazon.

Let the stain sit for about 5 minutes and then wipe it with a clean rag. Don’t wipe the stain away, just blend it so that they stain is even over the piece.

Once the stain has dried (about 1 hour) you an distress it if you want a more rustic look. I used my Ryobi 18-volt orbital sander. I use the Corner Cat a lot but this piece is pretty large and this sander was faster.

Here you can see the difference in the distressed color and the original color. A lot of people ask how we get the stain to look the way we do and this is how 🙂

I tried the table top on for size. I didn’t attach it to the base yet because it would have been too hard to get in the house.

Once I brought it in the house, I used 4″ wood screws to attach the table top onto the supports.

Now for the top coat. I like to apply my polyurethane inside the house. There’s no sawdust in the air and it’s not 100 degrees 😉

I love to use the Varathane Triple Thick Polyurethane in Satin! It goes on equal to 3 coats of regular polyurethane. This is water based so there really isn’t a smell and it’s easy to clean up. I applied one coat with a bristle paint brush and let it dry. You can find the Triple Thick HERE on Amazon.

That was it! I built a bench to fit the bay window (plans for that coming soon) added some cute pillows and awesome chairs and now I have a functional and beautiful kitchen nook 🙂

Not bad for $75 in lumber right? 😉

Here is more info on the items in the pics 🙂

Tassel Pillow – HERE

Other pillows – HomeGoods

Chairs – HERE

Bench – Free plans coming soon!

Chalkboard Calendar – HERE

Stools – HomeGoods

Tile – HERE

Chandelier – HERE

Window Box Cornices – HERE

White Pitcher – HERE

Paint Colors – HERE

Window Shades – HERE

Used these plans to make a base for my custom built poker table. Would live to share a picture 🙂

Great plans, thanks!

I’m so disappointed. Disappointed in you two and in myself. I printed the plans and probably should have pulled up this post on my phone in the work shop as well. The written instructions don’t say anything about pocket holes on the base until step 4, AFTER the feet are too big to fit in my K5! I had to go buy a K3 and clamp just to drill the pocket holes on the tops of the feet. But I still couldn’t drill the pocket holes for the bottom side of the feet because the foot pads were in the way. Sooo, I drilled them into the sides and used pocket hole plugs to fill them. Oh, and the materials list includes 1″ brad nails, but the instructions say 1-1/4″ brad nails. And why would you not start with gluing the 1 x 8 pieces so they’d be dry and ready to use when the time came? Again, another tidbit included in the online post, but not in the instructions.

Still a gorgeous project. And I’m proud of myself for being able to adapt and improvise. I’m building two of these pedestals to go under my existing rectangular table top. They’re so sturdy! And I still love you guys. 🙂

You didn’t need to buy a different pocket hole jig. I used my k5, just temoved the threaded clamp press to provide the extra room, then stuck some 1/2” plywood in between to keep it tight in the jig.

Maybe read the plans all the way through before you start cutting and attaching

I really need a 36″ table. Do you think this base would be too large?

How do you keep any of your table tops from bowing or warping?

How do you keep any of your table tops from bowing or warping?

sealed all round

I am always so jealous of the both of you girls! YOU ARE SO TALENTED!!!! I LOVE everything about this picture!!! Do you have a plan on how you made your banquet benches? I’m really wanting to get this done for our nook. I think all of this would look great in our little corner!!

I need this table!

LOVE this! I wonder how difficult it would be to make a leaf for this? It would require 2 smaller pedestals.

There was no mention of a product used prior to painting to prevent the Resins from the knots on the pine wood from showing up in the future as ugly spots when they come through the paint. Do you treat the knots with any product prior to applying the paint?

Beautiful table! If I made the table top 60″, would I need to adjust the base design?

What type of finish did you use for the antique white paint? Satin or semi-gloss?

What router bit would you use to cut out the circle? I have a router but not sure what type of bit to purchase.

Thank you so much for these plans! Do you have any special tips for making the table top perfectly circular when you are marking the circle by hand with the pencil and then the jig saw? I cut a circular top with another one of your plans before and I made lots of mistakes if I didn’t hold the jig saw perfectly.

You girls are incredible! I love to build things and my fiancé and I are buying our first house (a fixer) and I can’t wait to complete all the projects off of your website including this gorgeous table to make it our own! Thank you for sharing all of the tutorials and instructions for free!!

What a gorgeous table!!! You girls are so talented! I am new to DIY and just completed the entryway bench that you posted a few years back. You have given me so much confidence and excitement in a new hobby! Thank you! Maybe one day I can make a table like this too!

This is exactly the table plan I was hoping you would add!!!! I almost had it figured out from the rectangular table with the similar base. One question, can this base handle a larger table top? I need a table to seat 6.

It can! Just make the top supports and feet longer according to the inches added to the top. Hope this helps!!

Finally! I have been waiting to see how you built this table. lol. But first lets discuss the chairs that are kinda stealing the show. LOVE THEM. I just want to know how comfortable they are, because I WANT them but my husband will complain if they are not comfortable. AND LORD knows we can’t have that. lol

Thank you!!! The chairs are AMAZING! Huge and comfy (I mean they are wood so it’s not soft comfy but they are giant and very comfy for kitchen/dining chairs! Most comfortable I have sat in!

Shanty2Chic can I use this base on the previous table you built? (octagon shape) I need a bigger table top but would prefer this base. Thank You