Learn how to build a farmhouse style dining table for $110 with free plans and a full tutorial. This design is inspired by Restoration Hardware and you can build this solid wood table for a fraction of the price!

Hey there! I’ve been moving right along trying to fill up all of the empty rooms in my new house. This week I moved into my dining room and I have been dying to build this Restoration Hardware inspired Dining Table since I started building my new house! You may have seen a sneak peak of this beauty on our Instagram! I love the look of a rustic dining table, like the boards came out of a 100-year-old building. Solid pine timbers never looked so good!

Make sure to follow us on Instagram and Pinterest to keep up with our most current projects!

Man I love this table! The farmhouse table that inspired it is a Restoration Hardware Table that costs $2,205 to purchase, before tax, and I built mine for $110! Wow, wow, wow! I still can’t believe it!

Table of Contents

How to Build a Farmhouse Dining Table

Supplies:

- 7 – 1x6x8 Pine or Whitewood Boards

- 8 – 2x4x8 Pine or Whitewood Boards

- 2 – 4x4x8 Pine or Whitewood Posts (can laminate 2 2×4’s)

- 1 1/4″ Pocket Hole Screws

- 2 1/2″ Pocket Hole Screws

- Kreg HD Screws (for 4×4’s)

- 1 1/4″ Brad Nails

- 2 1/2″ Wood Screws

- Wood Glue

- Stain and/or Paint

Tools:

- Miter Saw

- Drill

- Kreg Jig

- Brad Nailer

Of course, we want you all to be able to build one too so we have FREE Printable plans for you! Just click the image below or HERE for the free Farmhouse Table Plans.

And, as always, I’ve provided my tutorial pictures to make it even easier for you to create your own! I love building farmhouse tables because you get so much bang for your work and money. They look intimidating but this one, especially, is VERY EASY to build! So, let’s build this DIY Restoration Hardware Dining Table!

Building the Table Top

I started by attaching the tabletop planks, with the 1×6 boards, to create the planked top!

First, I used my Kreg Jig set at 3/4″ to drill pocket holes around the edges of the boards.

- You can find the Kreg Jig HERE on Amazon.

Next, I used 1 1/4″ screws to attach the boards. To create a smooth surface and to keep the top from bowing, just clamp each pocket joint as you go. We love our Kreg Face Clamp for planking table tops.

- You can find the Kreg Jig Face Clamps HERE on Amazon.

Easy enough! Time for the table top trim!

Make sure to measure and cut as you go for the trim pieces.

I started by cutting the long side pieces to size. Then, I attached them to the sides of the table top with 1 1/4″ pocket hole screws and wood glue.

I followed up by measuring for the width of the table top. I cut my end trim pieces to size and attached them with 1 1/4″ pocket hole screws from the end of each plank, into the trim pieces.

Step 2: Building the Base of the Table

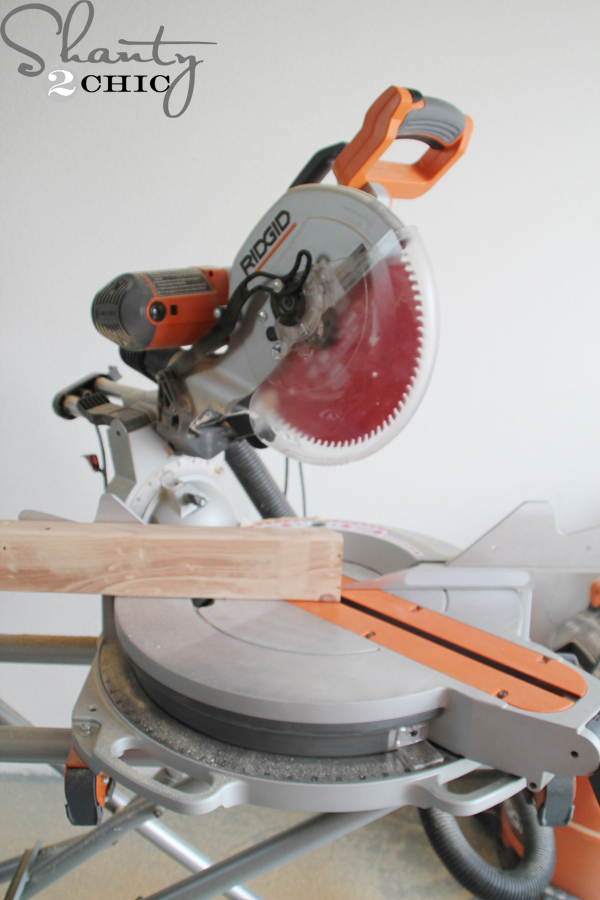

I used my Ridgid 12″ sliding compound miter saw to cut the 4×4 table base pieces.

Here’s a pic of the 45 degree miter that you will need to cut for the feet.

Before assembling the pieces, I gave them a good sanding with my Corner Cat sander. I don’t always do this before assembly but the 4×4’s were dirty and pretty rough. I used a 50-grit sanding pad for this. I used a 50-grit sanding pad for this and sanded with the grain of the boards.

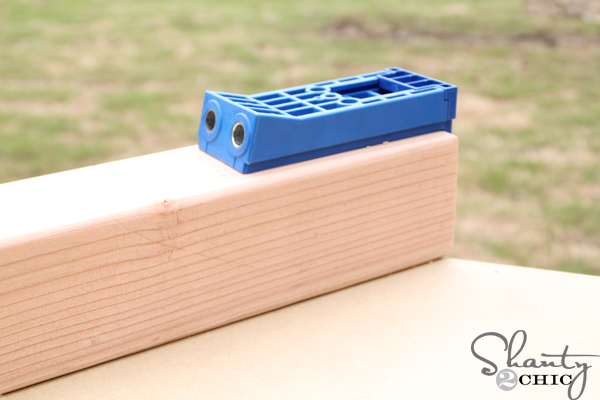

To attach the 4×4 leg pieces together , I used my Kreg HD to drill the pocket holes into the long base runner. It’s super easy, just clamp and drill! I attached the runner to the feet with Kreg HD screws.

- You can find the Kreg Jig HD HERE on Amazon.

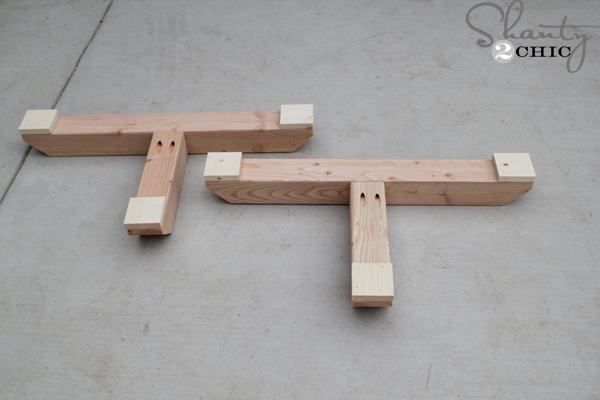

Here is the runners and the feet assembled. Don’t use wood glue here because this is a temporary assembly just to establish the pocket hole joints. After assembled, remove the stretcher.

Then, attach the short feet.

With the table feet upside down, attach a foot pad to each foot.

Flip the feet right-side-up and attach the table legs.

Then, start stacking the 2×4 cuts on top of the legs. I used 2 1/2″ spax screws. They are a bit pricey for wood screws but you don’t have to pre-drill!

Here are the legs completely assembled and now, believe it or not, it’s time to stain! Don’t assemble the table yet, stain first!

Step 3: Staining the DIY Dining Table

Before staining, we like to use the water-popping technique. Just use a damp cloth to wipe the entire table down and let it dry.

I chose Carrington by Rust-Oleum to finish the table. Just wipe on one-coat with a dry cloth, wait 5-minutes to let it sit, then wipe with another clean cloth to blend it. Make it your own with any finish you like! We love the variety of stains that Rust-oleum carries!

- You can find Rust-oleum Stain HERE on Amazon

I wanted the table to look worn so I used my Ryobi Corner Cat sander to distress all over. I used an 80-grit sanding pad for this part. (I didn’t decide to do this until the table was inside and assembled. It made a big mess so if you know you will do this, do it before you bring it inside.

I did add 3 coats of Varathayne polyurethane to the table in, matte finish, with a bristle brush. The matte gives it a very natural finish and protects the table top from minor spills. Now the table top is more kid-friendly 😉 I would still use coasters and placemats when using the table but this finish makes clean up super easy!

- You can find the Poly HERE on Amazon

Step 4: Attaching the Table Top to the Table Base

To attach these angle pieces we suggest screws in the plans. However, if you have a nailer, that will work great! If you choose to use wood screws, just predrill from the top of the angle piece into the leg post at an angle (bottom pieces angle down, top pieces angle up). Follow with 2″ wood screws and fill your screw holes with wood filler.

LOVE it 🙂

I love my new dining room table! Now I need to get busy on the benches and filling up the rest of the room! I have to say that this is by far my favorite Farmhouse Table that I have built so far! It completely transformed my dining room and it adds the perfect touch of farmhouse style!

Free plans for the matching benches can be found HERE

Thanks so much for stopping by 🙂 – Ashley

Curious about some of the other things you have seen in this room? Just click the links below for more info!

Pottery Barn Inspired Pallet Art

We have built a ton of gorgeous farmhouse tables over the years! You can click the images below for more free Dining Table Plans.

Looking for more styles? We have a complete list of over 25 DIY dining table plans so you can find the design that suites you best!