Oh HEY guys! For those of you that follow us on Instagram, you have seen the progress of this baby I am sharing today. I am in LOVE… With a table. Not ashamed.

I loved my old dining set, but have always wanted to build one myself for my fam. With 5 kiddos under the age of 11, we live a casual lifestyle, and I avoid cushions if at all possible. Casual doesn’t have to be simple and boring though! So, I enlisted the help of my sweet, furniture planning guru, Miss Ana White to help me come up with this BEAUTIFUL and beefy DIY farmhouse dining table…

Isn’t is the bomb?? Too legit to quit! Restoration Hardware wants $3000 for it… I made it for $100 in wood.

I am going to share lots of tips and tricks on building this right here, and you can see the full set of free plans for the table on Ana’s site!

Let’s get started!

I knew I wanted this table to be big and beefy, so I was immediately drawn to using 4×4’s for the base. These are beautiful and cheap at the same time. There are some things you need to remember though. Because of their thickness, some saws won’t be able to cut them. A 12″ miter saw should do the trick perfectly.

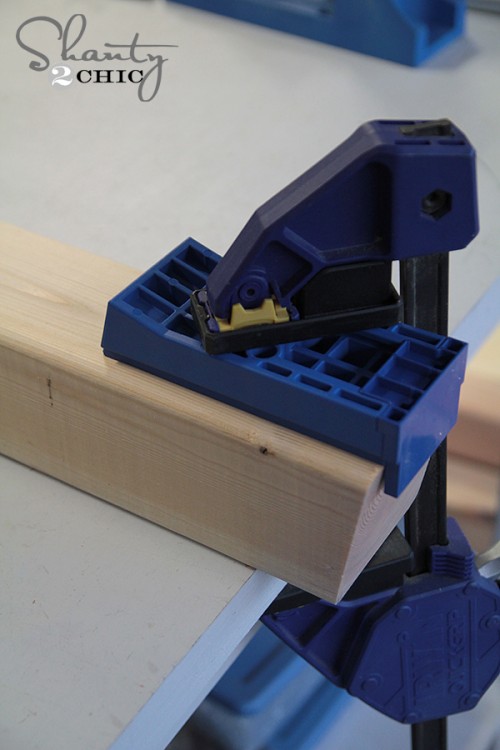

I was so excited to finally get to bust open my Kreg HD Jig!

I’ve actually had it staring at me in a box for months because I was too intimidated to open it up. I avoid learning new things, and then once I see how easy they are, I want to hit myself for not doing them sooner.

So, basically the Kreg HD Jig is a larger version of the Kreg Jig. It’s perfect for working with big projects like this one, since you won’t be able to fit these 4×4’s into the Kreg Jig. Here is what it looks like and how I clamped it on to my boards.

I used my Ryobi 18V drill to make the pocket holes. These pocket holes are bigger and thicker than the ones made with the regular Kreg Jig.

I took lots of photos of where I put my pocket holes on the base because sometimes figuring out the best places to put them is the biggest battle. You have lots of options, but here is where I decided to put mine…

I also used Gorilla Wood Glue between all of my joints!

This is a shot of the top of the base turned upside down on the ground. I put the pocket holes where they would stay very hidden.

That is a shot of the 2×4 runners that will go just beneath the table top.

Now for the diagonal pieces… Sometimes these can be a booger to clamp. In fact, I spent a good 10 minutes trying to hold one in place and then I finally had a light bulb moment and pulled out my Gorilla Tape. That stuff worked like a charm! I know it’s not the most beautiful clamping job, but hey… It held those pieces perfectly and cost a whole lot less than all of my clamps. We will call this part Shanty Clamping 😉

On this part, I just used 3″ wood screws through the diagonal pieces and into the straight pieces. You can see where my screws are in these pics…

I used 4″ screws on this part and went through the bottom runner and into the diagonal part.

Don’t clamp. Use the tape. Trust me.

And finally the table top. Oh the darn table top. This is actually a breeze to put together with a Kreg Jig IF you can find nice boards. I seriously made 4 trips to different hardware stores to find boards straight enough to work with. I actually ended up settling on 10 footers just to get good boards that would work. Oh well!

You can see how I put pocket holes up and down the boards to connect them. I clearly didn’t measure at all on this part… Just used the old eyeball method!

Because my wood was acting up a bit, you can see where I used multiple pocket holes on the breadboard… I won. It’s not going anywhere now.

I attached the base of the table to the top by using 2 1/2″ wood screws through the 2×4 runners. I also used a few 4″ screws through the 4×4 base just for added strength.

And now for the finish! Woohoo!

I decided to match the finish of the table to the Restoration Hardware sideboard and hutch I made for my dining room HERE.

I used Rustoleum Ultimate Wood Stain in Dark Walnut! You can find it at Lowe’s, but do know that the packaging has changed a bit.

This stuff is so great! It only requires 1 coat and it dries in under an hour. I have used many stains, and this brand is BY FAR my very favorite!

Once it dried, I put 2 coats of Rustoleum Ultimate Polyurethane in Satin on it to protect the finish. This goes on white and dries clear. It doesn’t stink and it dries fast!

That’s it for the finish!

I am in the middle of making the cutest benches to match this table. I LOVE a dining table with benches for my family. The kids can’t ruin them, and they are rustic and beautiful at the same time. I knew I wanted to dress the table up a bit with some end chairs, so I went to my very favorite store to find those!

I love them! Ironically, they match my window panels I made perfectly. It was a match made in dining room heaven… Or Homegoods! Aren’t they perfect??

And here are a few more shots!

I hope you love it as much as I do!!

I would LOVE for you to share this and PIN it with your peeps below!

Thank you so much for stopping by, and let me know if you have any questions at all. Thanks again 🙂

~Whitney

I really love the table ….. Looking forward to making one for our new house. I also like your chandelier, would you share with me where you got it?

I absolutely love this gonna try to make this. How long did it take to make?

What kind of wood did you use?

Stunning transformation it is ! Love the DIY dining table that you have done. It is the kind of table where I would love to host a lunch or coffee with my family :* … This DIY is on the top of my list now. Thanks for sharing it up here <3

Love & hugs

Jessica x

WOW…AWESOME table!!!! Amazing job!

Do you have any suggestions about using this as an outdoor table. I would use pressure treated wood. My concern is how to attach the table top pieces with a small space between each 2 x 10.(I would increase the length of the breadboard to account for the small gaps.) That takes out the options of using the Kreg, but I also do not want to have exposed screws on the top to attach it to the base. Anyone have ideas for me?

Your 4×4 runners under the table do run the width of the table, but there is nothing to keep the center down and keep it from bowing. YOu can do 4 1/2″ screws from below on the 4×4’s, but I think you will want to add additional pieces in the center to keep the wood from bowing up on you. Hope this helps!

Can I use the K4 for this project?

Love this! Just what we’re looking for with our family of 6. Any ideas on what bench plans would go with it?

I’m working on them now, and should have the plans up next week!

Can you post a link here, if you have them? Thx!

Where did you find your 4×4 boards? The only ones we have here are treated. I’ve also built a ton of furniture for our home, but always end up laminating 2 2/4’s together for chunky legs. Did you order them?

All of my Lowe’s and HD’s carry them in untreated pine. Not sure about your location though! Sorry!

Question! For the poly finish, how do you both apply (on larger projects like this of course)? I am SO afraid for this part of the table we built because I don’t want to mess it up. The table is so big, I don’t want to get half of it done and then it dry and look terrible. Any suggestions? Good thing I called Dad because I was about to put it in the spray gun and call it a wonderful day!

In my experience spraying it on will get you the best finish and will be by far faster. However, I’ve brushed on poly a ton of times on table tops. As long as it isn’t super hot in your space you should have plenty of time to finish the table before it dries. Just don’t go back over where you started once you get to the end.

PS if you choose to spray it makes a mess so be prepared.

I always brush it on and it’s great – very smooth. Go in thin layers, no bubbles or drips, and lightly hand sand with fine grit sandpaper in between in coat but not after the last coat. I usually do 2-3 coats on a table for extra durability, but you can do more or less depending on the look and shine you want. Don’t be scared! It will be beautiful! 🙂

Love it, how pretty and such a great tutorial too. Hugs, Marty

Thanks Marty!

Love the look, it’s gorgeous. We have 5 kiddos aged 11 and down also… I’m wondering, what do you do with the crumbs that inevitably end up in the cracks between the wood on the table top? We built your outdoor table and benches for our covered deck (loving It, by the way!), but I’m finding it difficult to keep the cracks between the boards clean. Do you caulk before applying the poly? Or just run a toothpick every week or so 🙂

If you have or have access to a table saw it would be easy to cut of the rounded sides of the top planks then glue, screw, and clamp and sand the top, preferably with a belt sander. You could even have them make the cuts at Lowes or wherever you buy the wood.

I suppose you could also use stainable wood filler but that would be pretty tedious.

Good Luck!!

Was thinking exactly the same thing. How do u stop or clean the crumbs.

I like to use the suction tube of my vacuum… Works like a charm 🙂

Very nice. I built a modified version of the original farmhouse table, but have been considering changing the base to something similar to this. I didn’t use wood glue between the base and the top for that very reason; easy to change out! My table is currently stained Early American, but thinking I may do an old world/chippy look on the new base.

As always, great work.

Thank you Jeff! I would love to see yours when you get it done! Sounds beautiful 🙂

Thanks for sharing

Thanks Linda!

Always look forward to your posts in my email. Your home is beautiful. I have a random question. What type of flooring am I always seeing in these gorgeous shots? Thanks

Stained concrete! I’m very jealous of your floors. VERY.

OK, thanks! Got any ideas or information on the ability or expense to put down this kind of flooring after tearing out carpeting?

My husband and I contemplated trying to do it ourselves, but it’s pretty complicated unless you have clean/new/chip-free concrete. We had glue and chunks missing from the carpet tack strips when we removed the carpet. Didn’t even try to tackle. I’ve read it’s about $4/ft professional, but never got an estimate. One day maybe. And in my next house.

Well, Shucks! We’re here to stay, so I guess that option might be out! Thanks, JennKay!

I agree… It was easier for us because we had the subs cover the floor and protect it when we built the house. Most concrete in existing homes will be covered with all kinds of goodness, some stains they won’t be able to remove. If it makes you feel any better, I am currently looking at new flooring to cover mine because these have been such a booger to keep clean. I feel like they are always dirty! Hope this helps!

I LOVE this table! This is exactly what I want my husband to build. The problem we’ve come across is that we can’t find untreated 4x4s….where did you get yours?

You can find them at Lowes, Homedepot, sutherlands, pretty much every box store that sells wood. IF they sell treated 4×4’s they will almost always sell untreated. Sometimes they are douglas fir instead of pine though. But fir seems to stain better then pine anyway.

Lowes and HD neither one sell untreated 4x4s in my area. I have heard of one local lumber supply that does, but haven’t went by and checked yet.

what area do you live in?

Central NC. At one time, both website’s showed that they carried them in store here, but when I went by, both told me that haven’t carried them in a while and actually recommended that other lumber supply.

That’s crazy a 4×4 post is a pretty standard piece of wood. Thats like them saying they no longer carry 2×4’s or screws.

Agreed. They always have tons of treated 4x’s. Just no untreated.

We don’t have them where I live in the lowcountry of SC either. I had that question, too. Maybe it’s the region we’re in. But, whenever I need a 4×4, I just have to laminate 2-2×4’s together. It still looks very good, but I’d love to have that single piece of 4×4.

I’ve done that before on a previous table, but I do like the look of a solid piece of wood. That’s a bummer that your stores don’t carry them!

Agreed! Here in Texas they stock them like all of the other lumber. I can always find them, and ours are always very straight too.

I am in TX and they only have treated pine, or cedar. That’s it!

That’s a bummer… I have had a few people mention that they can’t get them. Like Nathan said, our stores always carry them. Bummer!